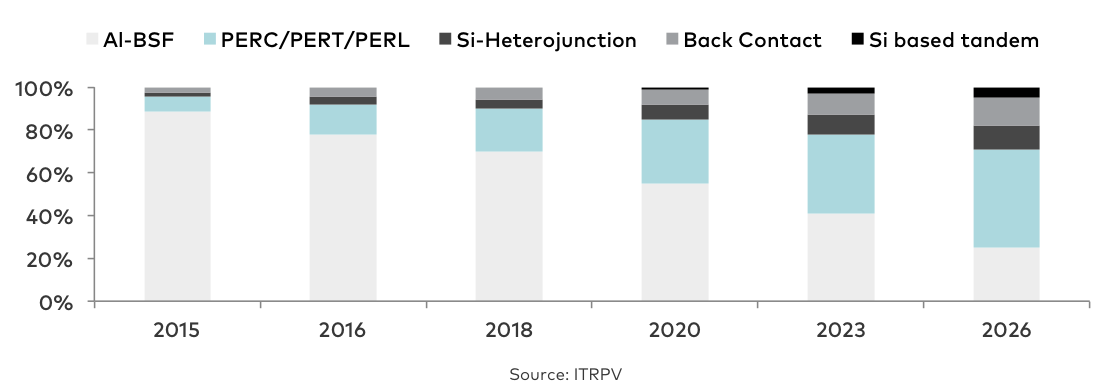

2022 is regarded as the first year for the development of N-type battery technology. According to statistics, by the end of 22, TOPCon and HJT’s landed production capacity reached 81GW and 13GW respectively. Considering that there are still about 1GW of xBC shipments in the market, the total shipment of N-type modules has reached about 20GW in 2022, and the proportion of total shipments of N-type modules has reached about 7%.

Among N-type technologies, TOPCon has proven that it has comparable or even better profitability than PERC. During the P-to-N technology iteration window period, traditional photovoltaic manufacturers have aggressively expanded their production capacity to consolidate their market positions. New entrants also hope that Relying on the advantages of no historical burden, the rapid production capacity layout can establish its own market share. As of February 23, it announced that the production capacity of high-efficiency battery technology has exceeded 1100GW, of which more than 850GW of new production capacity chooses TOPCon technology.

TOPCon Development Status

According to InfoLink statistics, the nominal production capacity of TOPCon is expected to reach 477GW by the end of 23, which means that the production capacity of TOPCon batteries by the end of 2023 will be equivalent to the existing PERC battery production capacity. In 2022, only Jinko has a 10GW TOPCon production capacity, but by the end of 2023, more than 17 manufacturers will have a 10GW and above production capacity. In addition, new entrants will also contribute more than 50GW of TOPCon production capacity in 2023.

In terms of efficiency, mainstream TOPCon battery manufacturers all claim that the efficiency is around 25.0%, and further gains of 0.2-0.3% can still be achieved by superimposing SE technology in the future. Look, the real efficiency is still around 24.2%, which is about 1% higher than the efficiency of PERC cells.

In terms of yield rate, the performance of each company is still quite different. Although the leading companies have achieved a level comparable to PERC, the yield rate of most manufacturers is still hovering at 95% or even less than 95%. Cost reduction is the top priority.

In terms of overseas production expansion, Southeast Asia is expected to add 21GW of TOPCon batteries in 2023, and India will also increase 6GW. Among them, TRW's 2GW in Thailand is already in the stage of ramping up its production capacity.

Competition of TOPCon technical route

The TOPCon production capacity in the market in 2023 and before was mainly based on the LPCVD route and the POPAID route dominated by Jolywood. Among them, LPCVD has become the most mainstream technology route because of the largest expansion of Jinko and Jietai. Although the LPCVD route technology is mature and the passivation effect is excellent, the low production capacity and the high cost of quartz parts have prevented the industry from giving up the research on the PECVD route. With the continuous breakthroughs in efficiency and yield of Tongwei and Trina PECVD routes, The potential cost advantage caused by the high production capacity of PECVD has attracted more and more manufacturers to expand production and choose this route.

As of February 2023, InfoLink differentiated based on the 326GW production capacity in production and under construction (equipment bidding completed) according to the Poly deposition route. Among them, the LPCVD route is mainly based on Jinke, Jietai and Longji, accounting for about 42% of the total ; while PECVD is mainly based on Tongwei, Trina, Shangji, Runyang, etc., accounting for about 52%; although the POPAID route has the advantages of fast film forming speed and no winding, the Uptime of plate equipment is relatively low, which leads to the audience Still less. At present, the LPCVD route is trying to upgrade from single-slot and single-insert to single-slot and double-insert to double the production capacity. It is estimated that the competition between the mainstream routes of LPCVD and PECVD will exist for a long time.

1. What does PERC mean?

1. What does PERC mean?